Maltodextrin is widely used in beverage, frozen food, candy, cereal, dairy products, health products and other industries. It can also be used in textile, daily chemical and pharmaceutical production.

Maltodextrin added to milk powder and other dairy products can make the product volume expand, not easy to agglomerate, instant, good mixing, prolong the shelf life of the product, reduce the cost and improve the economic benefit.It can also improve the nutritional ratio, improve the nutritional price, and be easy to digest and absorb.The role of maltodextrin in the preparation of functional milk powder, especially sucrose free milk powder and infant feeding milk powder, has been confirmed. The dosage is 5% ~ 20%

It is used in nutritious snack foods such as soybean milk powder, instant cereal and wheat milk essence. It has good taste and instant thickening effect, avoids precipitation and stratification, it can absorb bean smell or milk smell and prolong the retention period. The reference dosage is 10% ~ 25%.

When used in solid drinks, such as milk tea, fruit crystal, instant tea and solid tea, it can maintain the characteristics and flavor of the original product, reduce the cost, the product has mellow and delicate taste, strong flavor, especially good instant effect and inhibit crystallization. Good emulsifying effect and obvious carrier effect. The reference dosage is 10% ~ 30%. The maltodextrin of DE24 ~ 29 suitable for the production of coffee partner can be used as much as 70%

It is used in frozen foods such as ice cream, ice cream or popsicle. The ice particles expand finely, have good viscosity, mild sweetness, little or no cholesterol, pure flavor, cool and clean mouth, good taste, and the dosage is 10% ~ 25%.

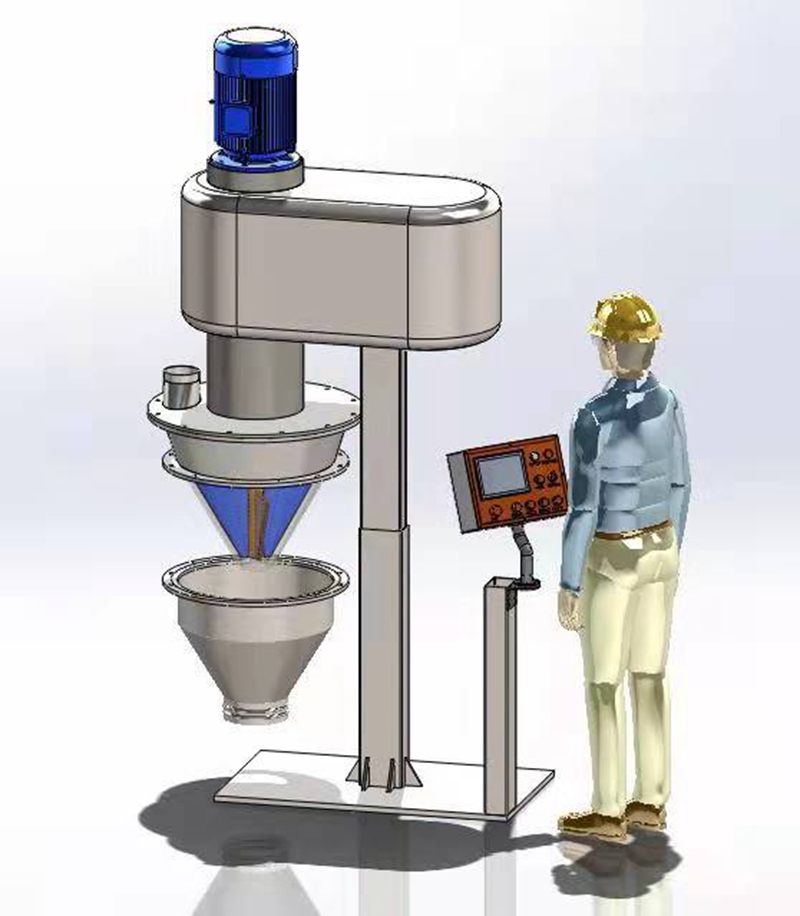

麦芽糊精生产工艺流程Maltodextrin production process flow

1.Preparation

Sent the starch milk to the liquefaction PH regulating tank, add Na2CO3 solution through the metering pump according to the flow rate of starch milk to adjust the pH continuously, and add a part of α- amylase to the liquefaction tank at the same time.

2.Liquefaction

The adjusted starch milk is pumped to the primary jet liquefier for primary liquefaction with steam, and the gelatinized starch solution is sent to the primary maintenance tank; then pump it to the secondary jet liquefier for secondary liquefaction with steam; Send the hydrolysate to the secondary maintenance tank. Another part of the liquefaction enzyme is added to the discharge pipe of the tank, and the solution is pumped into the continuous plunger flow reactor to complete liquefaction. Part of the liquefied solution is sent as the raw material for maltose syrup. The temperature is cooled to 70 ℃ and then enters the saccharification unit.

3.Vacuum drum filtration

Liquefied maltodextrin contains a lot of protein insoluble impurities that are difficult to filter out, so diatomite precoating vacuum drum filter is adopted. Because the filter cake on the surface of diatomite is removed and continuously updated, the filtration is fast and in-depth.

4.Decolorization and filtration

Add activated carbon into maltodextrin sugar solution to absorb organic impurities (mainly soluble colored impurities), and then filter the activated carbon together with the filtered impurities.

5. Ion exchange

After filtration of soluble impurities and insoluble impurities, there are still some inorganic impurities in maltodextrin sugar solution in the form of cations and anions. The purpose of ion exchange is to remove them. The cations in the saccharification are exchanged with the H + of the cation exchange resin, while the anions are exchanged with the OH - of the anion exchange resin. Then the H + and OH - exchanged in the saccharification are combined into water, and the inorganic impurities enter the corresponding water for filtration.

Of course, in order to maintain the exchangeability of the exchange resin, when the exchangeability is weakened, the cation resin and anion resin are regenerated with acid and alkali respectively

6.Vacuum concentration

The syrup after ion exchange is partially removed by multi effect vacuum falling film evaporator, and the concentration is increased from 35% to about 60%.

7.Spray drying

The Maltdextrin crystals after vacuum concentration were dried by plunger pump and sprayed, and the powdered solid maltodextrin was obtained.

8.Packing

Pack according to customer needs and convenient transportation